Introduction

In contemporary Automated Manufacturing Defect Detection , ensuring product quality is essential for sustaining customer confidence and enhancing operational efficiency. Conventional methods of defect detection, such as manual inspections, are often labor-intensive and susceptible to inaccuracies. The emergence of Artificial Intelligence (AI) and Machine Learning (ML) has enabled manufacturers to adopt real-time defect detection systems that significantly improve precision, minimize waste, and boost overall production efficiency.

The Necessity for Real-Time Defect Detection

Manufacturing defects can result in higher costs, delays in production, and customer dissatisfaction. Several prevalent challenges in defect detection include:

Human Error: Manual inspections can be inconsistent and are influenced by the fatigue and expertise of the inspector.

Delayed Detection: Traditional techniques may uncover defects too late, leading to the wastage of materials and resources.

Scalability Issues: As production levels rise, manual inspections become less efficient and more expensive.

To address these challenges, AI-driven real-time defect detection offers a dependable and scalable solution.

How AI and Machine Learning Facilitate Defect Detection

Artificial Intelligence (AI) and Machine Learning (ML) employ sophisticated algorithms to analyze images, identify anomalies, and classify defective items in real-time. The primary technologies involved are:

1. Computer Vision for Image Inspection

Machine Learning models, trained on extensive datasets of product images, can swiftly identify deviations and highlight defects. High-resolution cameras and sensors capture images in real-time, which AI then examines for:

- Surface flaws

- Dimensional discrepancies

- Color variations

2. Deep Learning for Recognizing Patterns

Convolutional Neural Networks (CNNs), a branch of deep learning, enable automated defect detection by learning from historical data. These models enhance their performance over time, leading to improved accuracy.

3. Internet of Things (IoT) and Edge Computing

Smart cameras and sensors equipped with IoT technology collaborate with AI models on edge devices to facilitate real-time defect detection, eliminating the need for cloud processing, which reduces latency and enhances speed.

Advantages of AI-Enhanced Defect Detection

The incorporation of AI in manufacturing defect detection presents several benefits:

- Enhanced Accuracy: AI minimizes human errors, ensuring consistent quality control.

- Immediate Detection: Prompt identification of defects prevents defective products from entering the market.Cost Savings: Early detection of defects reduces waste, rework, and material loss.

- Scalability: AI-driven systems can efficiently manage large-scale production lines.

- Predictive Maintenance: AI not only identifies defects but also forecasts equipment failures, thereby minimizing downtime.

Case Study: AI Implementation in the Automotive Sector

A prominent automotive manufacturer has adopted AI-driven defect detection through the use of machine learning algorithms and high-resolution imaging technology. The outcomes of this initiative included:

- 99% accuracy in identifying defective components.

- A 40% decrease in waste due to timely detection.

- Enhanced production efficiency through automated quality assurance processes.

This case exemplifies the significant impact of AI in maintaining product quality.

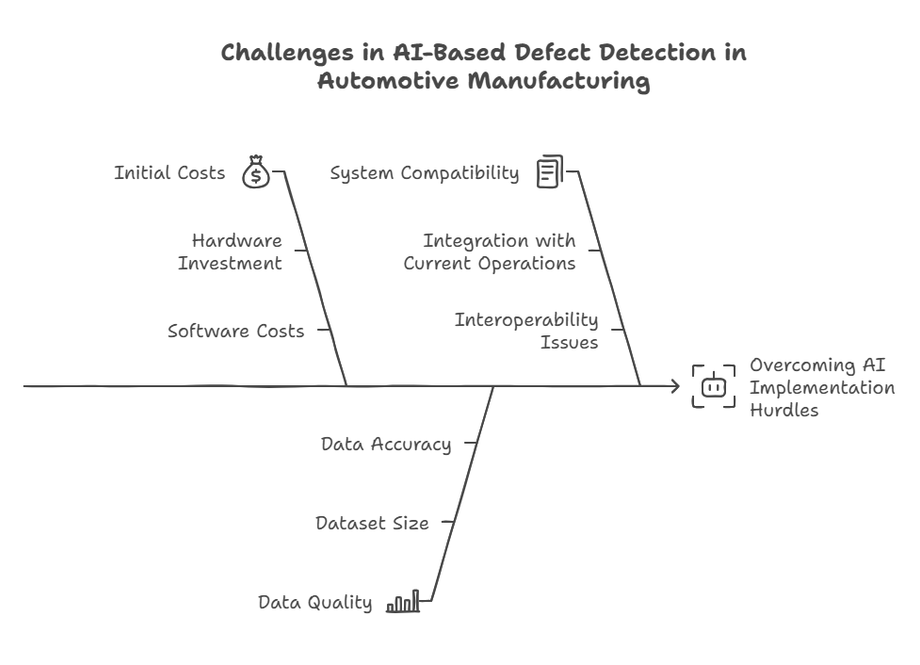

Challenges in Adopting AI for Defect Detection

Despite the considerable advantages of AI-based defect detection, several challenges must be addressed:

- Substantial Initial Costs: The deployment of AI necessitates investment in hardware, software, and specialized knowledge.

- Data Quality Concerns: Machine learning models depend on extensive, high-quality datasets to deliver precise predictions.

- Compatibility with Existing Systems: AI models need to integrate smoothly with current manufacturing operations.

The Future of AI in Quality Control within Manufacturing

The fields of AI and machine learning are advancing swiftly, featuring innovations such as self-learning AI models, enhanced deep learning methodologies, and real-time data analysis. Anticipated future developments include:

- AI-Driven Predictive Quality Control: AI will proactively modify manufacturing parameters to avert defects before they arise.

- Integration with Robotics: AI-enabled robotic systems will autonomously inspect and eliminate defective items from production lines.

- Cloud-Based AI Solutions: Improved collaboration and remote oversight of manufacturing facilities through AI cloud technologies.

Conclusion

The implementation of AI for real-time defect detection is transforming quality control in manufacturing. By harnessing AI, companies can improve accuracy, lower costs, and boost production efficiency. As AI technology progresses, the manufacturing landscape will increasingly become more intelligent, efficient, and dependable.

Are you prepared to incorporate Global Technosol AI-driven defect detection into your manufacturing operations? Begin today to elevate your quality control processes!